About Us

We are pleased to introduce our company M/s. Induction Equipment (India) Pvt Ltd (A Company subject to direction and coordination of Park Ohio Holdings Corp. USA) as one of the leading Induction Equipment manufacturers in India. With 30+ years of expertise of Induction Heat Treatment Machines. We have served OEMs, Tier 1 and Tier 2 customer based in India and across the Globe.

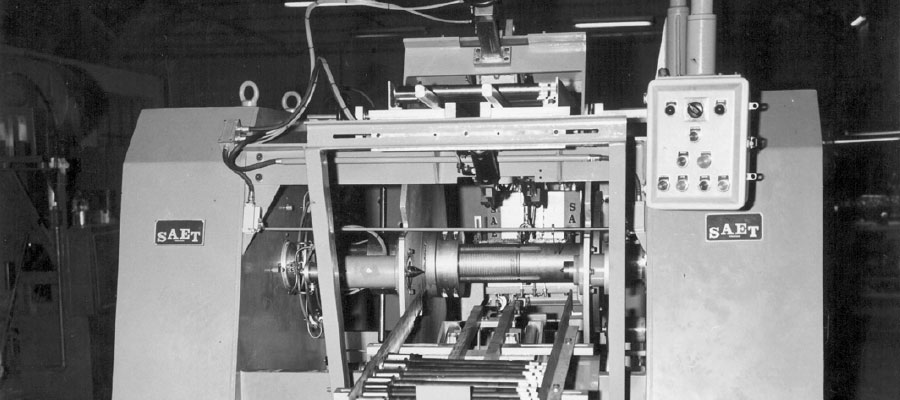

We are a part of SAET Spa Italy (A Group Company of Ajax Tocco Magnethermic Corporation Group of Companies), and have full fledge manufacturing plant in Pune, India.

To be your global partner for induction, we take pride in offering:

- Superior technology at reasonable prices,

- Fast and efficient services,

- Features and configurations of equipment to international standards,

- Excellent Process Technology support to the customer,

- European technology with Indian Flexibility.

WHY INDUCTION EQUIPMENT INDIA - Why Choose Us?

At IEI, we take great pride in offering top-notch induction Hardening equipment. Our commitment to excellence and dedication to our customers make us a preferred choice in the industry. Here’s why you should choose us for your induction equipment needs:

As part of the esteemed SAET Spa Italy and Ajax Tocco Magnethermic Corporation Group of Companies, Induction Equipment (India) Pvt Ltd boasts a rich heritage and global experience in the field of induction heating and hardening machines. With access to over 60 years of expertise, we stay at the forefront of technological advancements and industry trends, enabling us to deliver cutting-edge solutions to our Indian clients. Our commitment to innovation and continuous improvement sets us apart as a trusted leader in the industry.

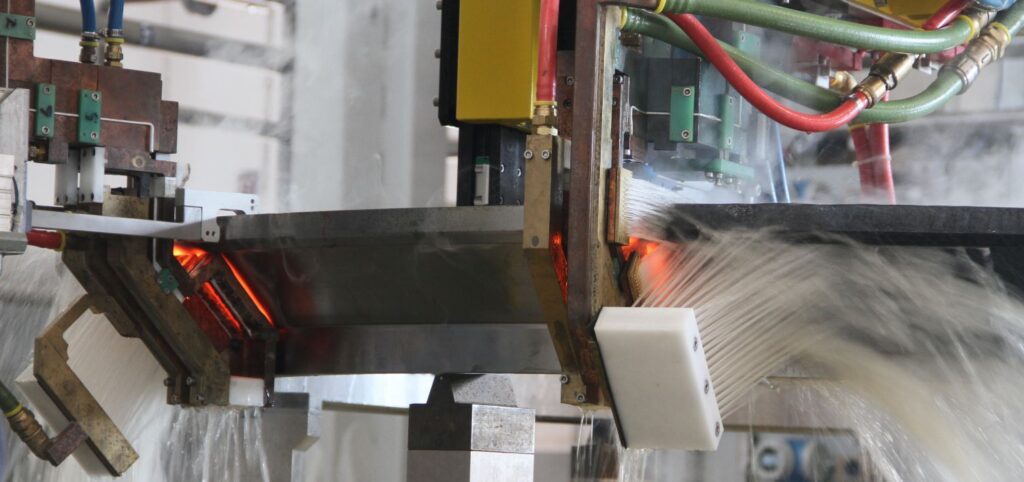

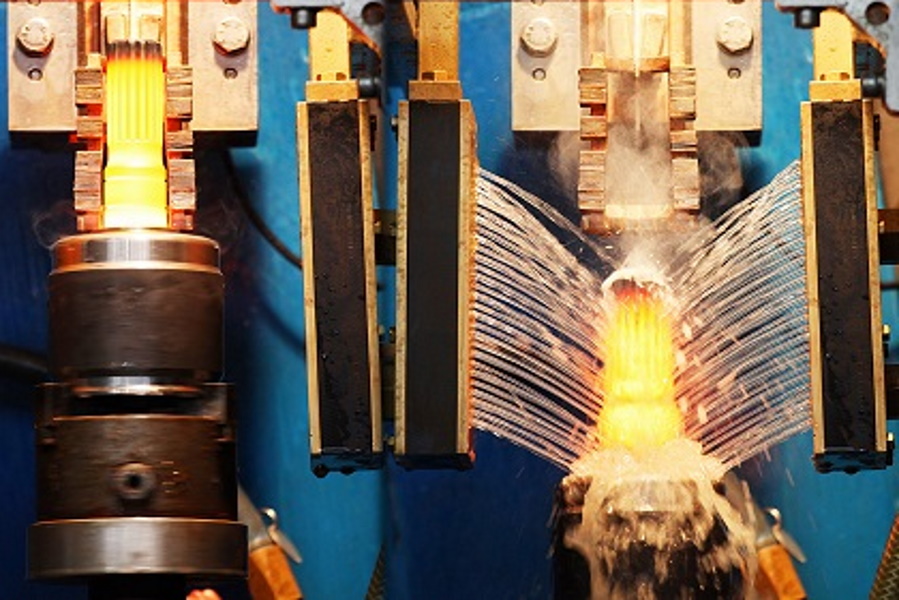

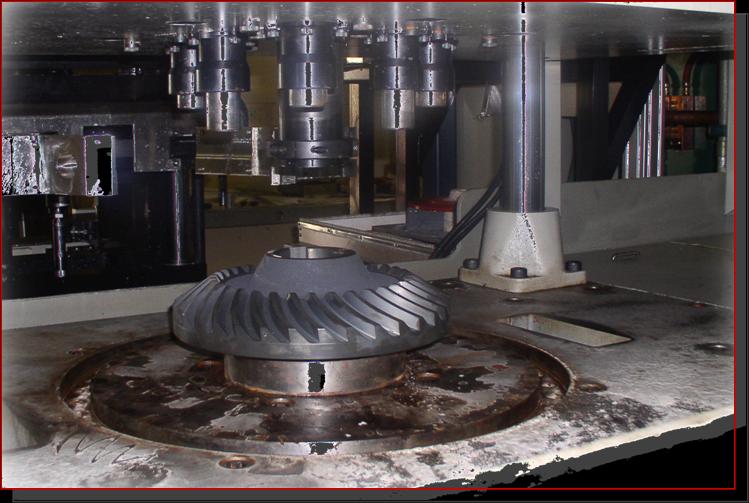

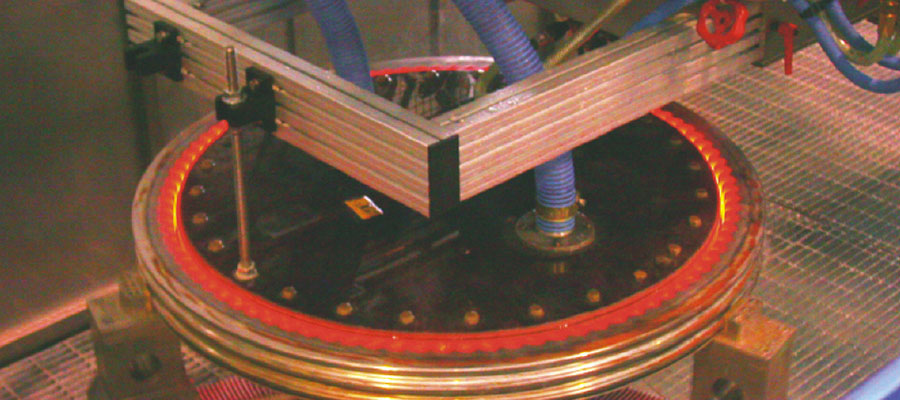

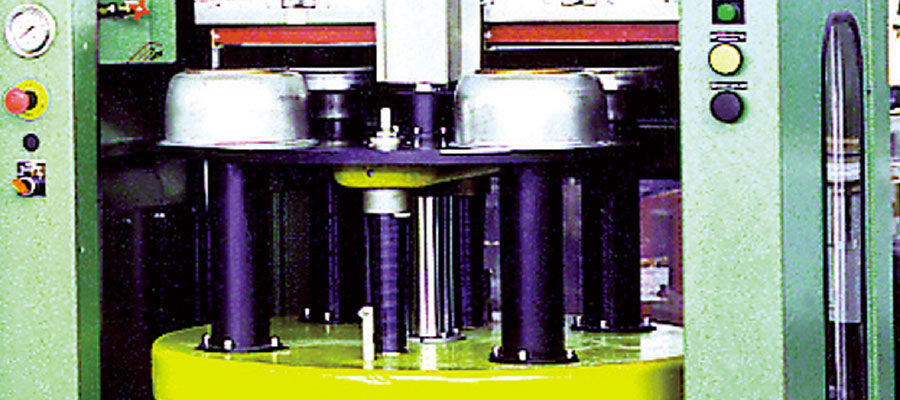

Our extensive product range includes induction hardening and tempering machines with range of power and frequency options. This diverse range of Product will provide you optimum solution in terms of Pattern, hardness and Case depth with specific needs of different industries, such as automotive, wind energy, aerospace, and more, providing them with tailored solutions.

Our expertise spans various heat treatment processes, including induction through hardening, case hardening, and annealing. With a wide range of power sources and frequency combinations, we can tailor our solutions to meet diverse heat treatment requirements effectively.

We take a tailored approach by considering customer metallurgical requirements and evaluating current processes. Embracing Industry 4.0 principles and machine automation, we provide cutting-edge solutions that keep our clients ahead in technological advancements.

Our cutting-edge Research and Development Center continuously innovates to elevate part quality and set realistic production expectations. We stay at the forefront of the industry, delivering state-of-the-art solutions to meet evolving needs

Our dedicated Aftermarket Spare Parts & Copper Products Group offers comprehensive support worldwide. From life support for induction machines to replacement parts and supplementary equipment, we keep your operations running efficiently.

At IEI, our Skilled technicians providing prompt, high-quality service for our Induction Hardening equipment across India & glob. On-site evaluations, repairs, upgrades – wherever you are, we’re there to support you. Customer satisfaction is our priority.

Choose Induction Equipment India for reliable, efficient, and precise induction equipment solutions that elevate your manufacturing processes to new heights. Join hands with us, and let’s power your success together.

Our experience

- Automobile components

- Off Highway Equipment & Heavy Machinery Parts

- Textile Machinery

- Construction Machinery, Mining & Agricultural

- Wind Energy & Ultra Large Bearing

- Aerospace

- Induction Billet Heating for Forging

Our strength

SAET GROUP JOURNEY