Billets Heating

Billets Heating

Billets heating is a process of heating metal billets to a specific temperature before further processing, such as forging, extrusion, or rolling. Billets are typically cylindrical or rectangular-shaped metal blocks that serve as raw material for subsequent manufacturing operations.

Billets heating refers to the process of applying heat to billets, which are semi-finished metal products with a square or round cross-section. Billets are typically heated for various purposes, such as improving workability, facilitating further processing, or preparing them for subsequent heat treatment operations.

Industries we serve:

What we do?

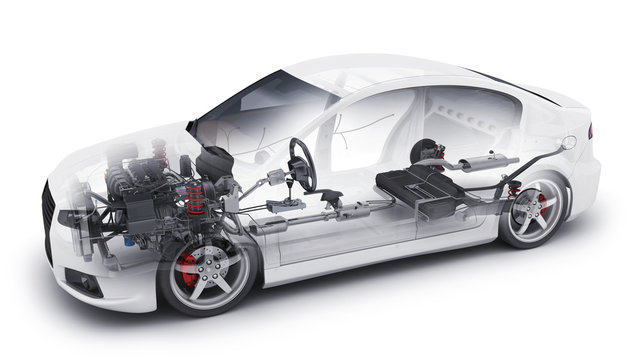

Automotive

Automotive Industries : Automotive In the automobile sector, the use...

Read MoreConstruction Machinery, Mining & Agriculture

Construction Machinery, Mining & Agriculture Industries : Construction Machinery, Mining...

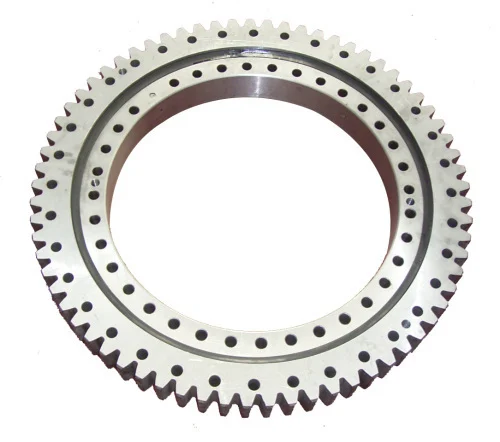

Read MoreWind Energy and Ultra Large Bearings

Wind Energy and Ultra Large Bearings Industries : Wind...

Read MoreBars, Billets & Tubes

Bars, Billets & Tubes Industries : Bars, Billets & Tubes...

Read MoreAerospace

Aerospace Industries : Aerospace The aerospace industry is a critical...

Read MoreFor more information contact us

Our Customer can benefit from the resources of a global corporation. We provide pan India assistance through our network of regional sales and services engineers.